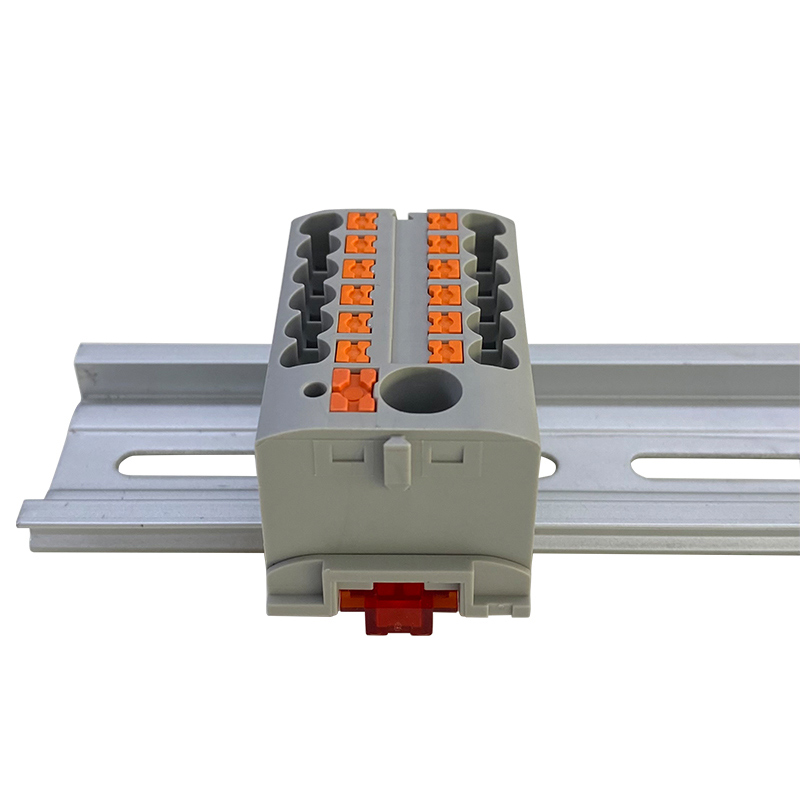

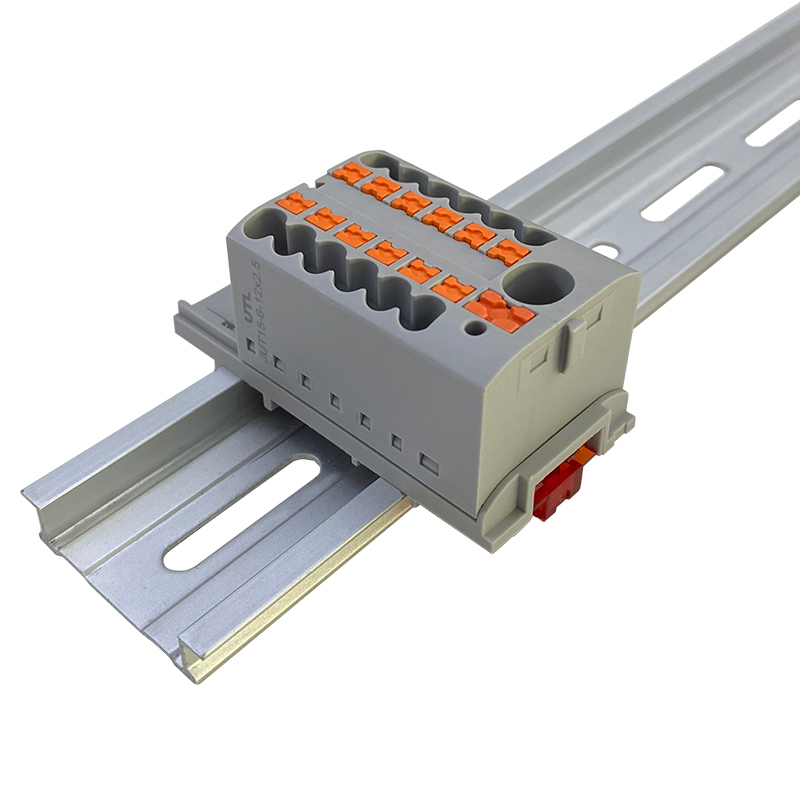

Advantage of JUT15-6-2.5P Series

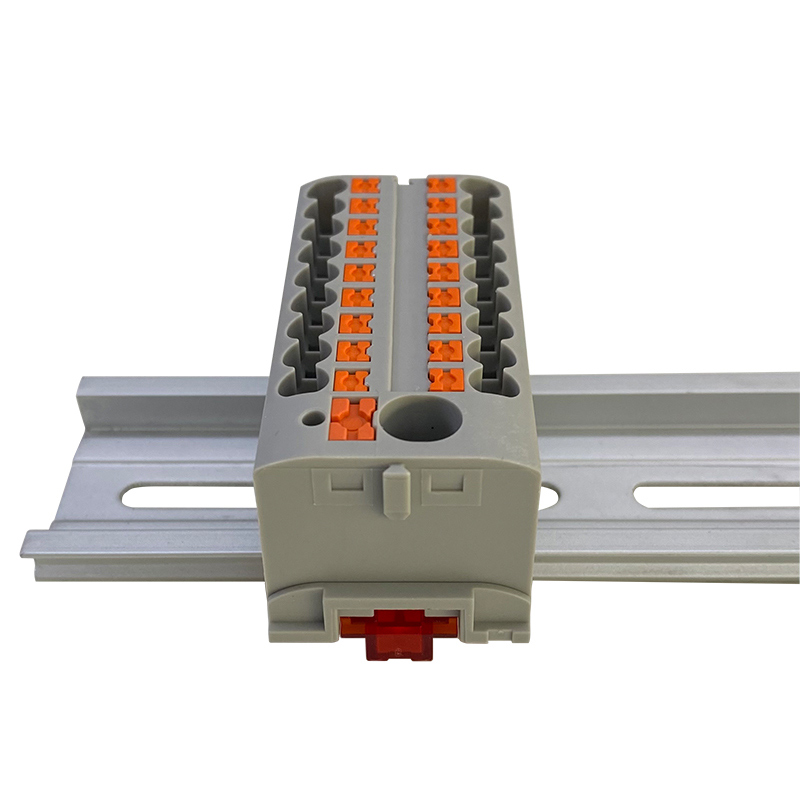

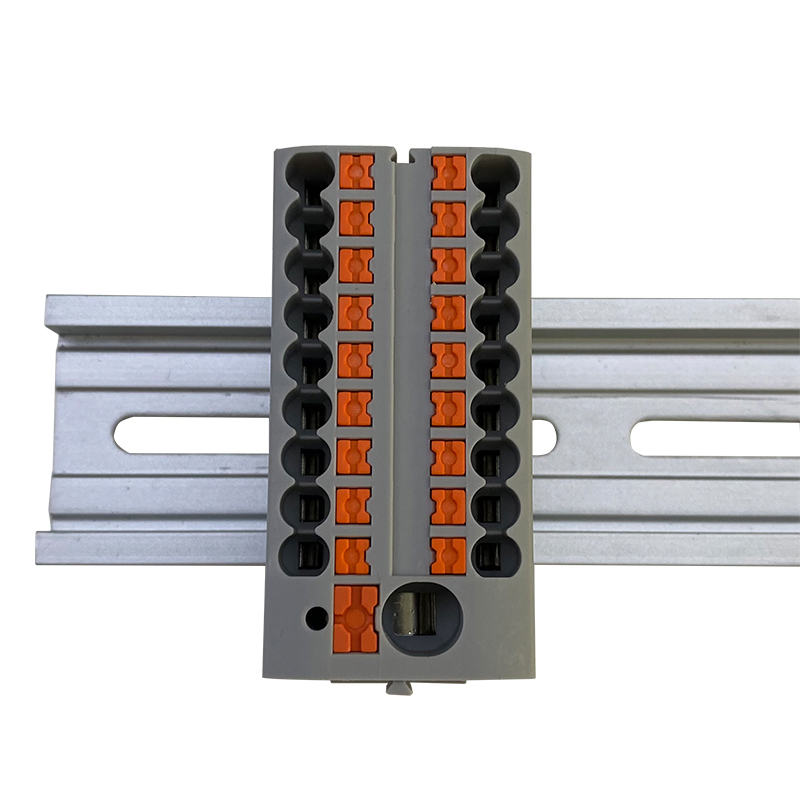

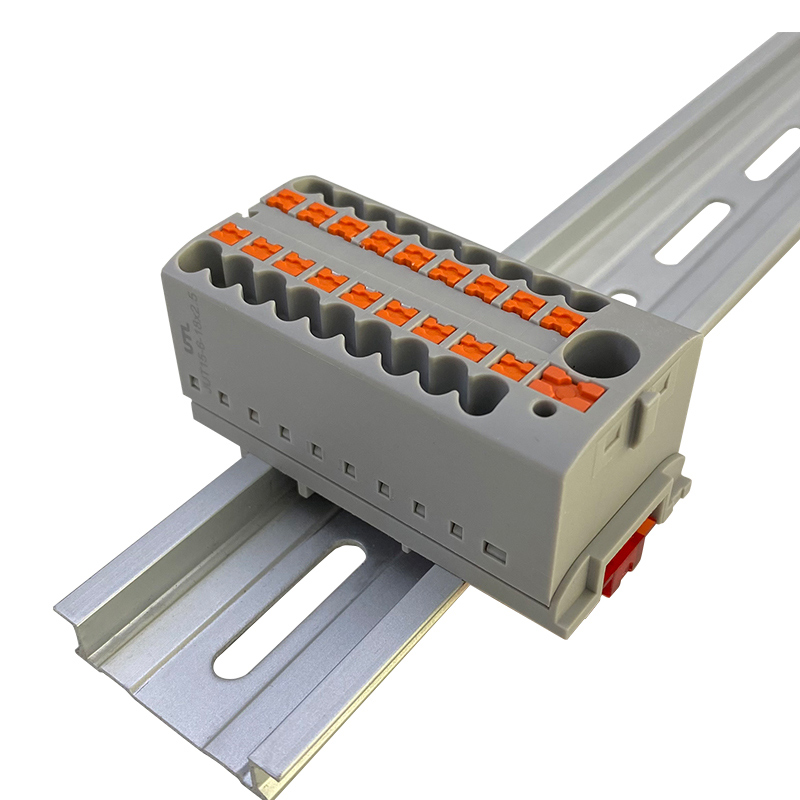

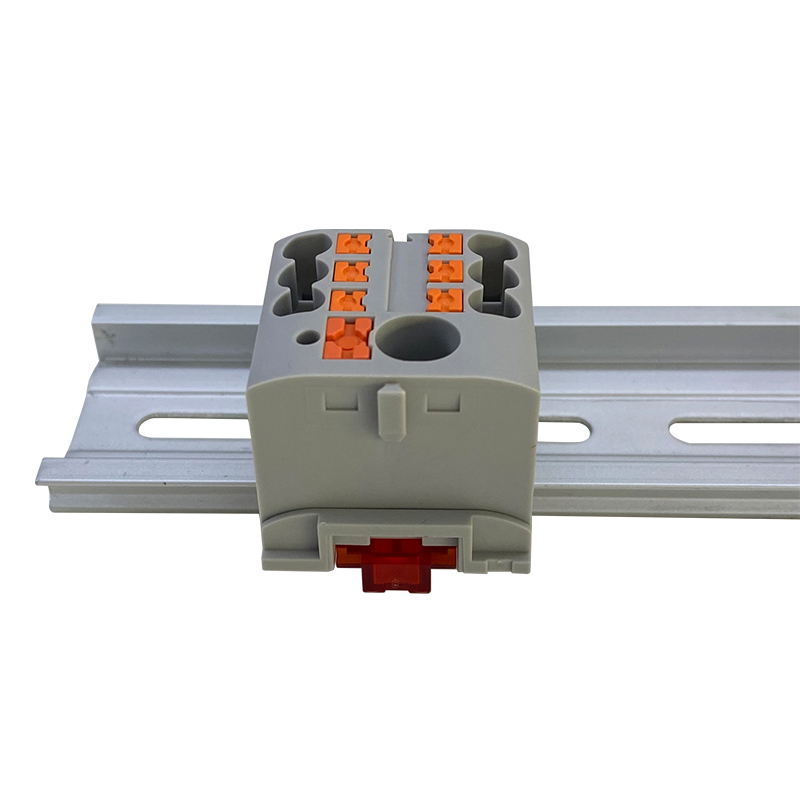

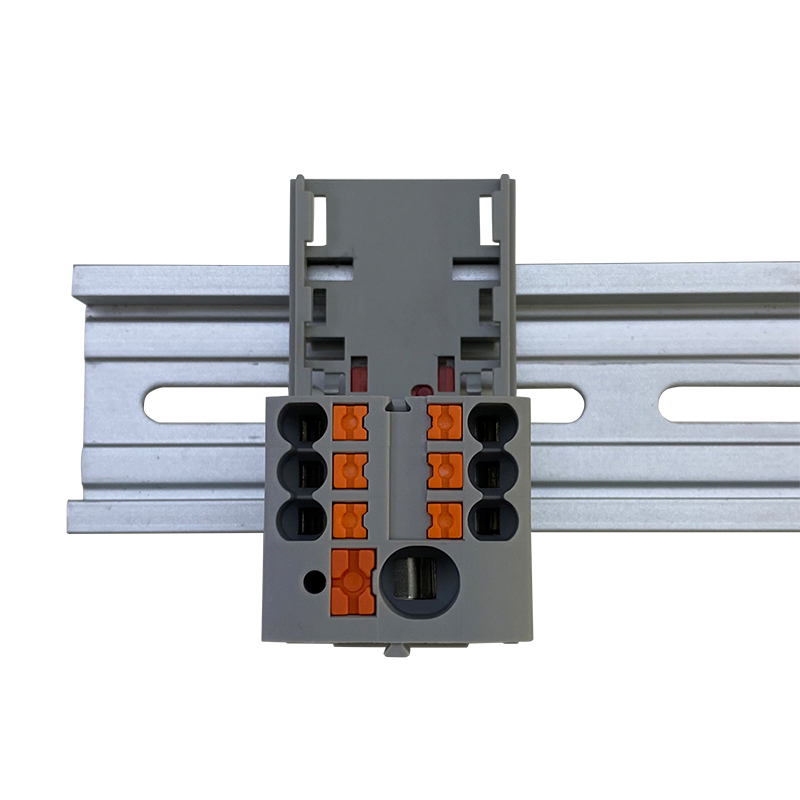

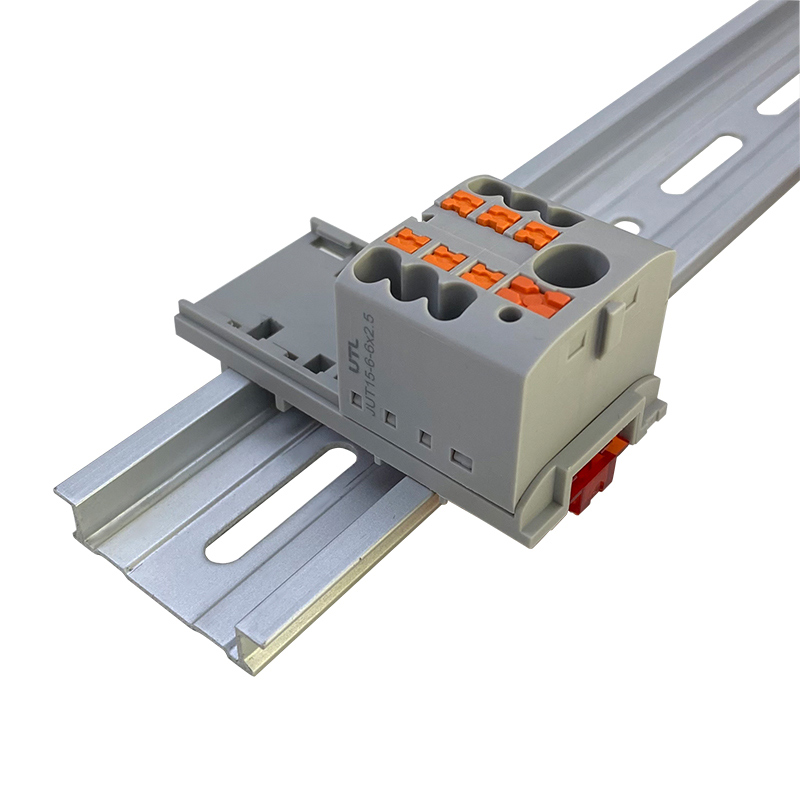

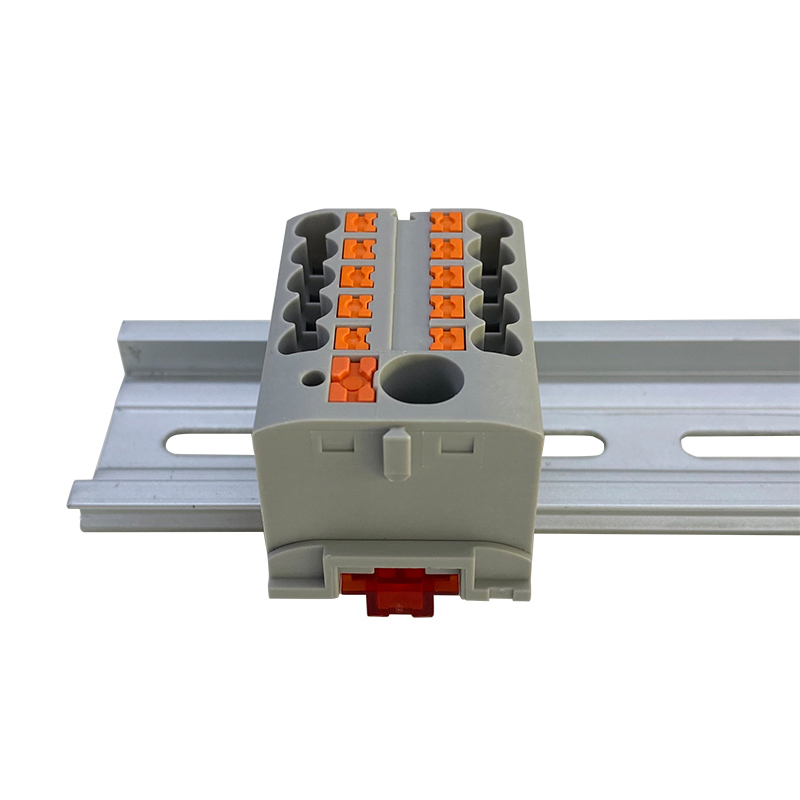

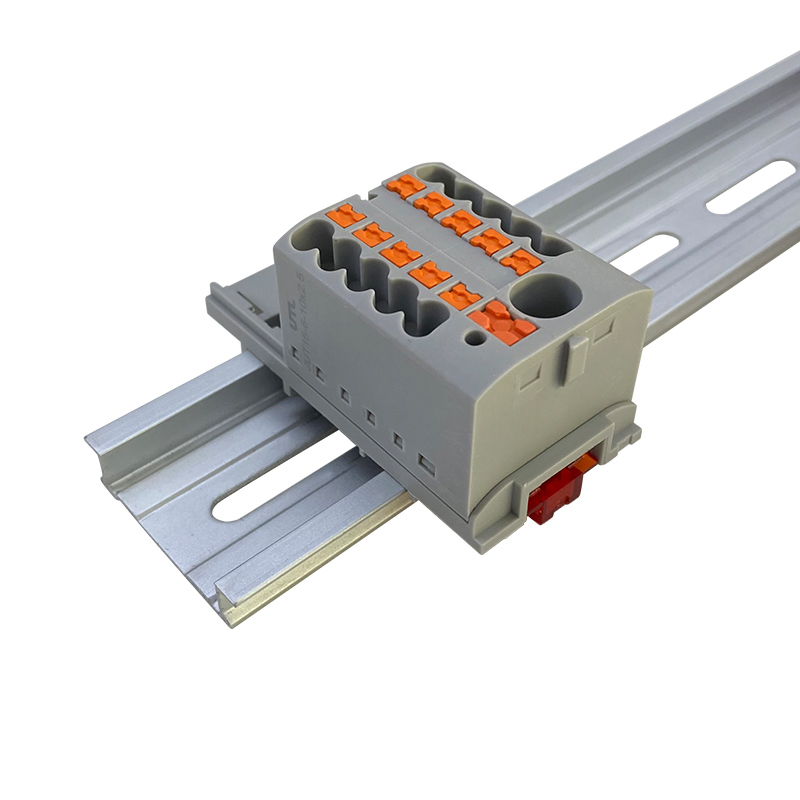

Can be installed vertically or parallel to DIN rail, saving up to 50% of rail space.

It can be installed by DIN rail, direct installation or adhesive installation, which is more flexible to use.

Time-saving wire connection thanks to tool-free push-in connection technology.

Modules can be installed immediately without manual bridging, saving up to 80% of time.

Different colors, the wiring is more clear.

JUT15-6-2.5P Series Description

| Product number | JUT15-6-4x2.5-P | JUT15-6-6x2.5-P | JUT15-6-10x2.5-P | JUT15-6-12x2.5-P | JUT15-6-18x2.5-P |

| product type | Din rail distribution terminal block | Din rail distribution terminal block | Din rail distribution terminal block | Din rail distribution terminal block | Din rail distribution terminal block |

| Mechanical structure | Push-in spring connection | Push-in spring connection | Push-in spring connection | Push-in spring connection | Push-in spring connection |

| layers | 1 | 1 | 1 | 1 | 1 |

| Electric Potential | 1 | 1 | 1 | 1 | 1 |

| connection volume | 5 | 7 | 11 | 13 | 19 |

| Rated cross section | 2.5 mm2 | 2.5 mm2 | 2.5mm2 | 2.5mm2 | 2.5mm2 |

| Rated current | 24A | 24A | 24A | 24A | 24A |

| Rated voltage | 690V | 690V | 690V | 690V | 690V |

| open side panel | no | no | no | no | no |

| grounding feet | no | no | no | no | no |

| other | The connecting rail needs to install the rail seat PAD-NS15/35 | The connecting rail needs to install the rail seat PAD-NS15/35 | The connecting rail needs to install the rail seat PAD-NS15/35 | The connecting rail needs to install the rail seat PAD-NS15/35 | The connecting rail needs to install the rail seat PAD-NS15/35 |

| Application field | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial | Widely used in electrical connection, industrial |

| color | gray、dark gray、green、yellow、cream、orange、black、red、blue、white、purple、Brown、customizable | gray、dark gray、green、yellow、cream、orange、black、red、blue、white、purple、Brown、customizable | gray、dark gray、green、yellow、cream、orange、black、red、blue、white、purple、Brown、customizable | gray、dark gray、green、yellow、cream、orange、black、red、blue、white、purple、Brown、customizable | gray、dark gray、green、yellow、cream、orange、black、red、blue、white、purple、Brown、customizable |

Wiring Data

| Wire contact | |||||

| Stripping length | 8mm —10mm | 8mm —10mm | 8mm —10mm | 8mm —10mm | 8mm —10mm |

| Rigid Conductor Cross Section | 0.14mm² — 4mm² | 0.14mm² — 4mm² | 0.14mm² — 4mm² | 0.14mm² — 4mm² | 0.14mm² — 4mm² |

| Flexible conductor cross section | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² | 0.14mm² — 2.5mm² |

| Rigid Conductor Cross Section AWG | 26-12 | 26-12 | 26-12 | 26-12 | 26-12 |

| Flexible Conductor Cross Section AWG | 26-14 | 26-14 | 26-14 | 26-14 | 26-14 |

| line contact | |||||

| Stripping length | 10mm —12mm | 10mm —12mm | 10mm —12mm | 10mm —12mm | 10mm —12mm |

| Rigid Conductor Cross Section | 0.2mm² — 4mm² | 0.2mm² — 4mm² | 0.2mm² — 4mm² | 0.2mm² — 4mm² | 0.2mm² — 4mm² |

| Flexible conductor cross section | 0.2mm² — 2.5mm² | 0.2mm² — 2.5mm² | 0.2mm² — 2.5mm² | 0.2mm² — 2.5mm² | 0.2mm² — 2.5mm² |

| Rigid Conductor Cross Section AWG | 20-8 | 20-8 | 20-8 | 20-8 | 20-8 |

| Flexible Conductor Cross Section AWG | 20-10 | 20-10 | 20-10 | 20-10 | 20-10 |

Size (This is the size of the JUT15P carrying rail holder PAD-NS15/35 installed on the rail)

| thickness | 28.8mm | 28.8mm | 28.8mm | 28.8mm | 28.8mm |

| width | 58.5mm | 58.5mm | 58.5mm | 58.5mm | 61.3mm |

| high | 21.7mm | 21.7mm | 21.7mm | 21.7mm | 21.7mm |

| NS35/7.5 high | 32.5mm | 32.5mm | 32.5mm | 32.5mm | 32.5mm |

| NS35/15 high | 40mm | 40mm | 40mm | 40mm | 40mm |

| NS15/5.5 high | 30.5mm | 30.5mm | 30.5mm | 30.5mm | 30.5mm |

Material Properties

| Flame retardant grade, comply with UL94 | V0 | V0 | V0 | V0 | V0 |

| Insulation Materials | PA | PA | PA | PA | PA |

| Insulation material group | I | I | I | I | I |

IEC Electrical Parameters

| standard test | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 |

| Rated voltage(III/3) | 690V | 690V | 690V | 690V | 690V |

| Rated current(III/3) | 24A | 24A | 24A | 24A | 24A |

| Rated surge voltage | 8kv | 8kv | 8kv | 8kv | 8kv |

| Overvoltage class | III | III | III | III | III |

| pollution level | 3 | 3 | 3 | 3 | 3 |

Electrical Performance Test

| Surge Voltage Test Results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

| Power frequency withstand voltage test results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

| Temperature rise test results | Passed the test | Passed the test | Passed the test | Passed the test | Passed the test |

Environmental Conditions

| Ambient temperature (operating) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics relative temperature) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics relative temperature) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics relative temperature) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics relative temperature) | -60 °C — 105 °C (Maximum short-term operating temperature, electrical characteristics relative temperature) |

| Ambient temperature (storage/transport) | -25 °C — 60 °C short term (up to 24 hours), -60 °C to +70 °C | -25 °C — 60 °C short term (up to 24 hours), -60 °C to +70 °C | -25 °C — 60 °C short term (up to 24 hours), -60 °C to +70 °C | -25 °C — 60 °C short term (up to 24 hours), -60 °C to +70 °C | -25 °C — 60 °C short term (up to 24 hours), -60 °C to +70 °C |

| Ambient temperature (assembled) | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C |

| Ambient temperature (execution) | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C | -5 °C — 70 °C |

| Relative Humidity (Storage/Transportation) | 30 % — 70 % | 30 % — 70 % | 30 % — 70 % | 30 % — 70 % | 30 % — 70 % |

Environmental Friendly

| RoHS | No excessive harmful substances | No excessive harmful substances | No excessive harmful substances | No excessive harmful substances | No excessive harmful substances |

Standards and Specifications

| Connections are standard | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 | IEC 60947-7-1 |

JUT15-6-6x2.5-P

JUT15-6-10x2.5-P

JUT15-6-12x2.5-P

JUT15-6-18x2.5-P